NAPCON Optimizer

Reach new heights with NAPCON Optimizer.

NAPCON Optimizer maximizes profit directly through plant-wide economic optimization. NAPCON Optimizer is based on dynamic real-time optimization concept, a state-of-the-art optimization technology. It is an ideal solution to ensure competitiveness at any market situation

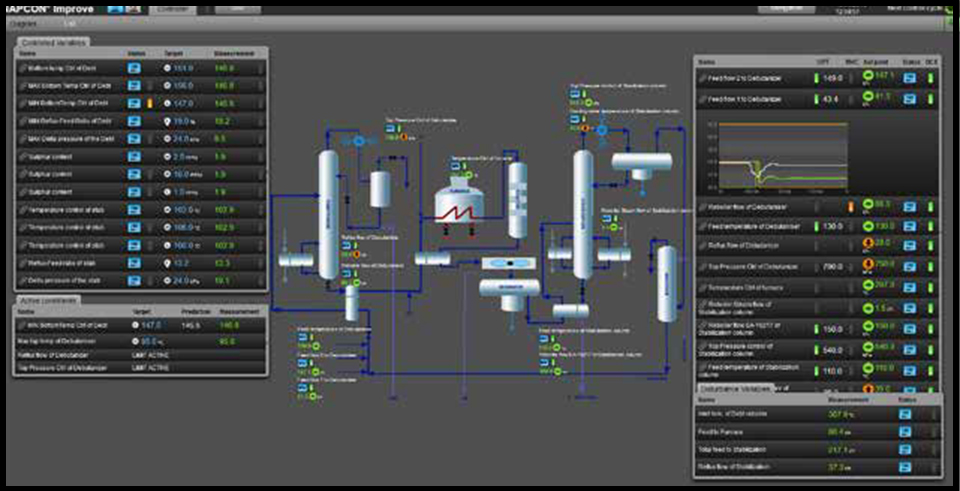

The usability of NAPCON Optimizer has been designed with panel operator’s work flow in mind. As plant-wide optimization applications are highly complex by nature, the user interface facilitates focusing on the most important topics that need operator attention.

NAPCON guarantees a fast return on investment through a secure and vendor-independent solution, based on our extensive knowledge on process design, automation and instrumentation.

Use NAPCON Optimizer for

Benefits for you

-

MAXIMIZED PROFIT

Plant-wide production optimization maximizes profits by taking into account product prices, as well as raw material and utility costs. -

EARLY START, EARLY CASH FLOW

The most beneficial part of the delivery scope will be implemented on a fast track. -

VENDOR INDEPENDENT

NAPCON Optimizer can be built on existing Advanced Process Control (APC) application from any vendor. -

AVOID SUB OPTIMIZATION

Plant-wide optimization makes sure that all process units operate towards common goal and there is no sub-optimization creating unwanted bottlenecks or costs. -

STAY UP TO DATE

NAPCON Optimizer includes an advanced monitoring and reporting system, making it an excellent tool for indicating process bottlenecks, which require separate actions to increase production capacity.

Key features

-

ECONOMIC OPTIMIZATION

NAPCON Optimizer maximizes production profits by economic optimization. It coordinates existing Advanced Process Control applications provided either by NAPCON or other vendors. -

FLEXIBLE TARGET SELECTION

The optimization objective function is adjustable, allowing flexible prioritization between economic optimization, production objectives, control targets and constraints. The objective function consists of product revenue, feedstock costs, utility costs and other relevant production costs and revenues. -

ON TOP

NAPCON Optimizer sits on top of advanced process control applications. It gives new target values for APC controlled variables and possibly new set points directly to certain DCS controllers. -

CONTINUOUSLY PERFORMED OPTIMIZATION

Optimization is continuously performed both during steady-state and process transients. A typical optimization execution cycle is 1 to 2 minutes. -

EASILY IMPLEMENTABLE INTERFACE

The NAPCON Optimizer functions on a standardized, modern and secure OPC UA interface, making it implementable on any platform.

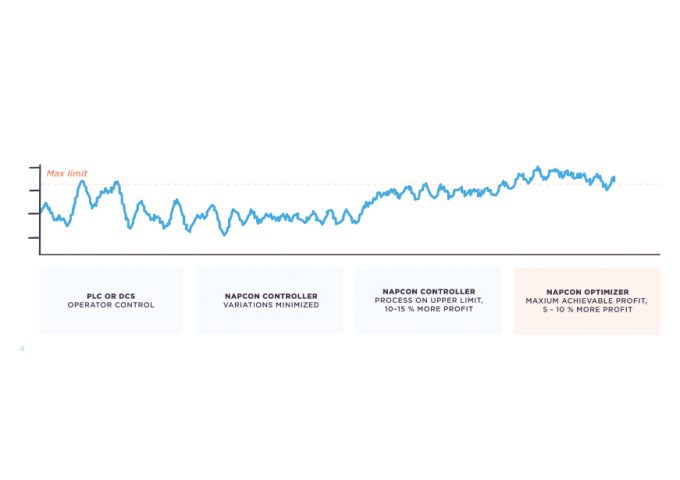

NAPCON CONTROLLER VS. NAPCON OPTIMIZER

NAPCON CONTROLLER

Although based on Model Predictive Control (MPC), NAPCON Controller is more than a mere software – it is a holistic solution for tackling a specific challenge in the production process. The NAPCON Controller is installed to control a certain process unit, where it is able to regulate wanted characteristics of the end product (e.g. humidity), decrease product variability and increase production.

NAPCON OPTIMIZER

is ideal for plant-wide production optimization. It covers all MPCs and utilizes Dynamic Real Time Optimization to conduct them, making it at least 30 times faster than traditional Real Time Optimizers. NAPCON OPTIMIZER enables you to choose certain holistic optimization targets that best suit your market situation: maximize production throughput, minimize utility costs and optimize your raw material usage. NAPCON Optimizer will then consider the price of raw material, your production line’s utility costs, and the selling price of the end product – and generate maximum profit.